Works - Photos

Ben Pearson

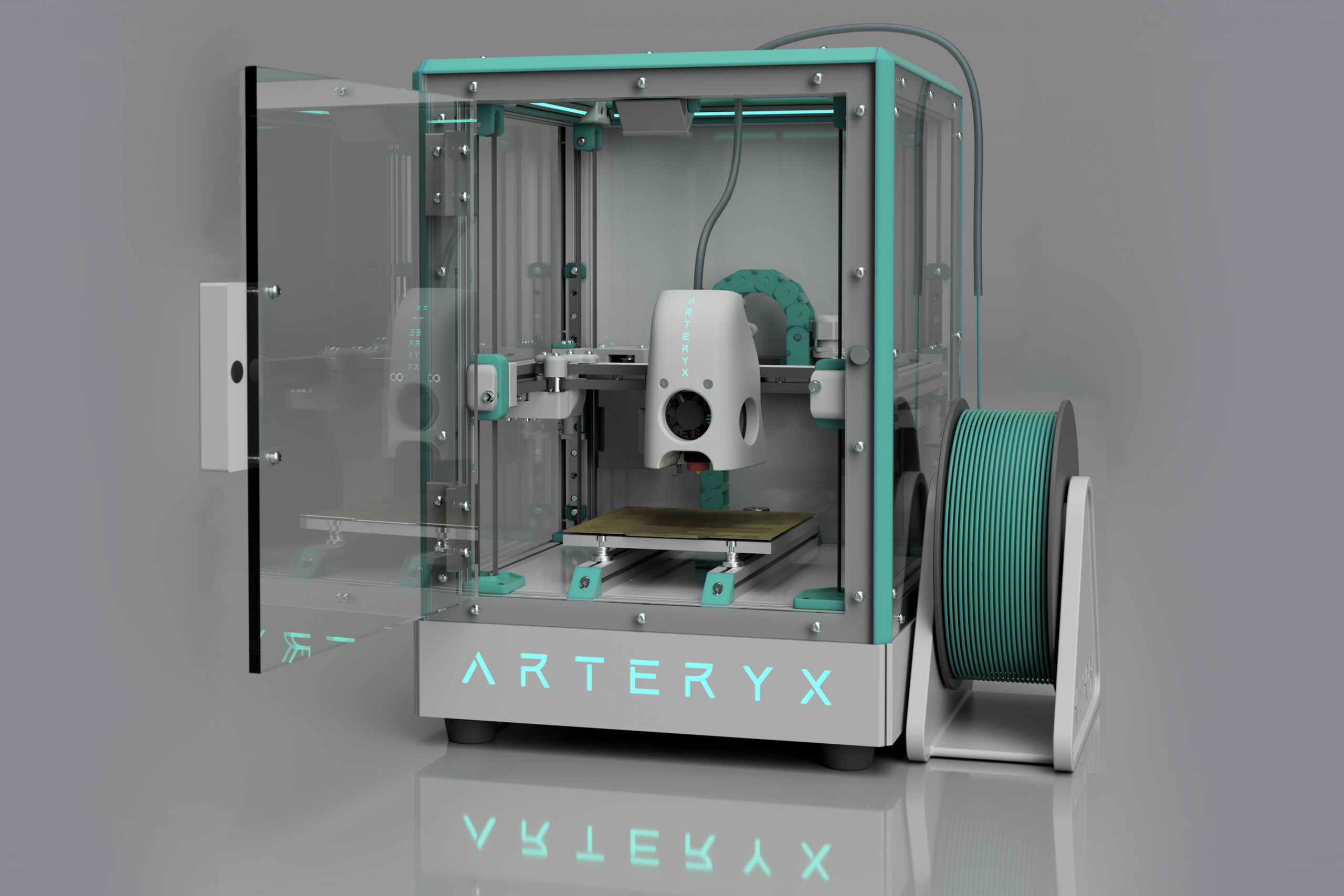

ARTERYX 3D Printer

The core principles underpinning the design were user upgradeability, simplicity of assembly and hardware compatibility. The use of modules for all electronic components means that the printer assembly process requires no soldering, wiring or crimping. A process that was previously a major barrier to entry for custom 3D printers is now less complex than building a desktop pc.

Ben Pearson

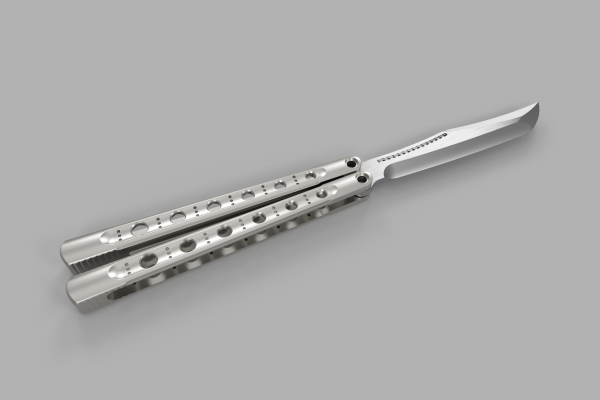

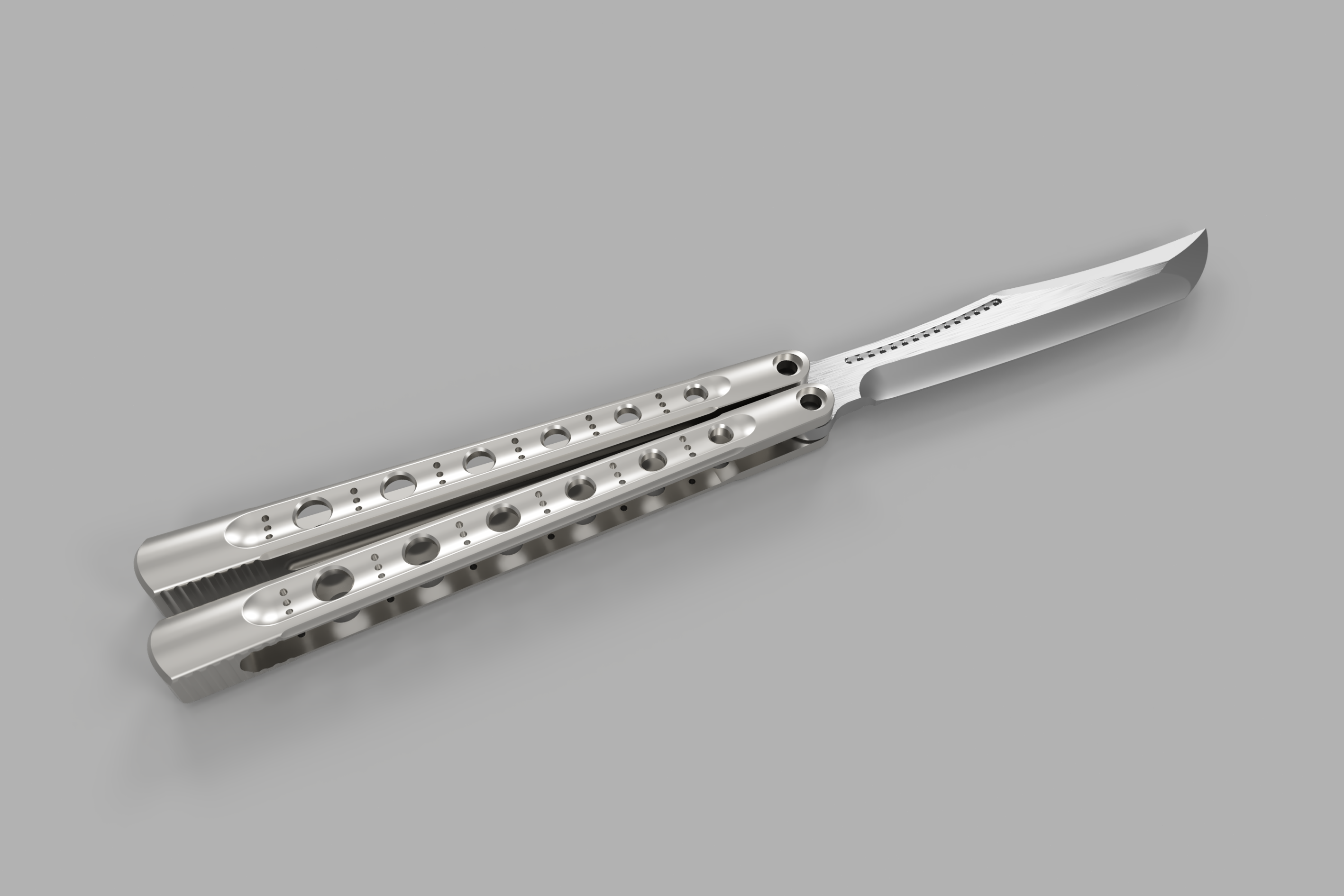

EMBER BALISONG

Designed in collaboration with a maker in the United States, this balisong is in its final testing phase before the first production run of 25 units. Parts of the design have a tolerance of one thou after machining, and were a real test of design for manufacture skills. Balisong flipping is a sport that has seen a lot of growth in the United States, with large competitions being held at events such as Blade Show West

Constructed from:

Blade: S35VN Steel

Handle: 6Al4V Titanium

Constructed from:

Blade: S35VN Steel

Handle: 6Al4V Titanium

Ben Pearson

SOS BALISONG

Designed in collaboration with another maker in the United States, this balisong has had it's first production run of 10 units. The handles featured a balance adjustment system, allowing the user to adjust the knife to their preferences. The tritium vials meant the knife to glow in low light, allowing for unique content creation.

Constructed from:

Blade: S35VN Steel Hardened to 58HRC

Handle: 6Al4V Titanium, with optional anodisation

Inserts: Titanium or twill carbon fiber, with the option for tritium vial inserts

Weights: 7075 Aluminium, 6Al4V Titanium, twill carbon fiber

Constructed from:

Blade: S35VN Steel Hardened to 58HRC

Handle: 6Al4V Titanium, with optional anodisation

Inserts: Titanium or twill carbon fiber, with the option for tritium vial inserts

Weights: 7075 Aluminium, 6Al4V Titanium, twill carbon fiber